Monoblock design refers to the production of different components as a single piece. This design is used in industrial equipment and is preferred to ensure durability and long service life. This structural form eliminates the need for assembling separate parts. In this way, it both shortens the assembly time and minimizes potential connection point failures. In engineering, this manufacturing approach offers reliable performance in systems exposed to high pressure and temperature.

Monoblock bodies are frequently used in machine parts, pump systems, mold technologies, and automotive components. Thanks to single-piece production, material strength increases and maintenance requirements decrease. Thus, operational costs are reduced in the long term. The key elements in this manufacturing method are high strength, precision machining techniques, and homogeneous material distribution. Therefore, these systems are highly important in terms of providing technical performance and operational efficiency.

What Does Monoblock Mean?

The question “What does monoblock mean?” is one of the most frequently asked in industrial equipment and cooling technologies.

This system is one in which all main components are gathered within a single body. This design refers to systems that offer an integrated structure. While this design approach ensures durability, it also offers advantages in terms of ease of use. In designs, especially in heat pump or cooling technologies, monoblock systems shorten assembly time and also allow for reduced maintenance needs.

Gathering different components in a single body instead of separate housings in monoblock structures both saves space and increases efficiency. One of the main features of such systems is their ability to provide reliable performance in cooling or heating needs. Especially with monoblock heat solutions, energy efficiency is ensured, and they are preferred for their long-lasting use.

The main advantages of monoblock systems are:

In industrial fields, monoblock cooling technologies are frequently preferred, especially for food preservation, as well as pharmaceutical storage and industrial cooling. These systems contribute to increasing the efficiency of businesses thanks to their features such as long-term energy savings and high performance.

Monoblock has a compact and efficient system design that gathers all components in a single body. This structure offers long-lasting and reliable solutions in cooling and heating applications.

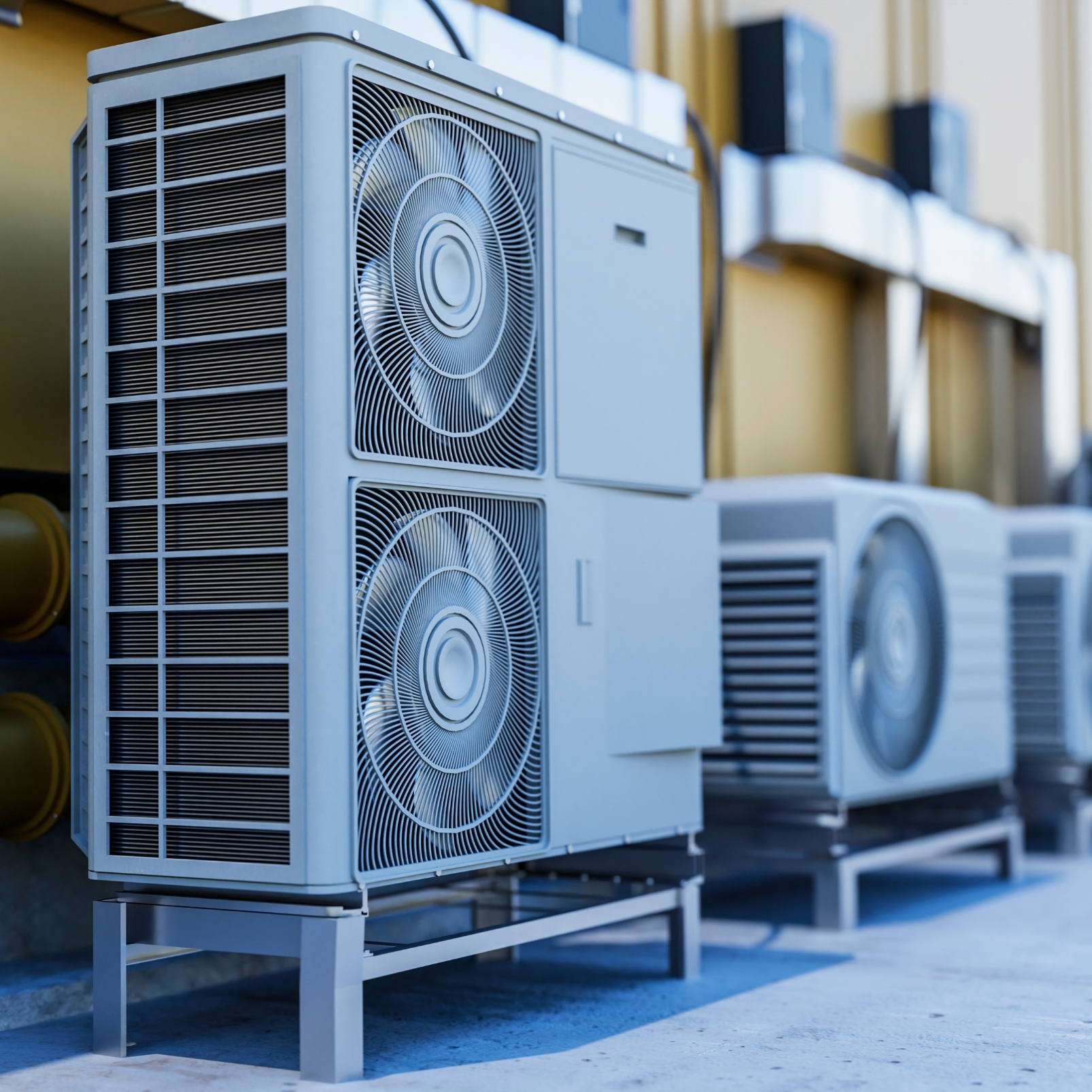

Monoblock Cooling Devices

Monoblock cooling devices are modern systems that have the feature of housing all main components within a single body during the cooling process. These devices are widely used in sectors where temperature control is of critical importance, such as food, pharmaceuticals, and chemicals. When combined with panel cooling technology, these devices ensure stored products remain fresh and safe.

Monoblock structures have many advantages. One of the most important is their ability to operate without the need for an external machine room. With this feature, they reduce both installation costs and occupied space. At the same time, the design of these devices prioritizes energy efficiency. Thus, they offer low operating costs during long-term use.

With the use of monoblock devices in industrial areas, all components of the cooling system are contained in a single unit. Therefore, maintenance and repair processes are quite easy. Thanks to high-performance fans, efficient compressors, and advanced control panels, these devices meet the cooling needs of businesses of all sizes.

In addition, monoblock devices used in industrial cooling carry a lower risk of malfunction compared to modular systems. For this reason, they stand out as a reliable solution in areas that require continuous operation, such as warehouses, restaurants, and markets. Monoblock cooling devices, with their compact structure, quick installation, and high energy savings, are an indispensable part of modern cooling technologies.

For detailed information about monoblock design, application areas, and the advantages it offers, you can contact Teknotek.