Knowing how a chiller works will help you decide which cooling system you want to install in your project.

The first answer to the question of how a chiller works is that there are two different operating principles, air-cooled and water-cooled. When buying chillers, it is necessary to consider the size of the place where the system will be installed, energy consumption, whether there are personnel to perform maintenance, desired cooling values, whether heating and cooling is required in the place or not.

How Does An Industrial Chiller Work?

First of all, let’s talk about the air chiller model. In this system, air cooling is used as natural or fan supported. If the natural air flow is insufficient to cool the part without increasing the surface, a chiller to be added to the part increases the heat transfer and reduces the temperature of the part by absorbing heat from the part. If more cooling is needed, a fan is added to increase the air flow over the chiller and allow more heat to pass through the air. Air chiller systems do not require additional equipment, while water chiller systems require some additional equipment.

However, although the energy consumption per unit basis is low, the total energy consumption in a given area is higher than the water chiller systems. Although the surface area is increased, the back pressure against the air blown by the fan increases as the chiller size and weight increase. As the fans grow, the fan itself and the mounting parts leads to a reaction in the cooling function.

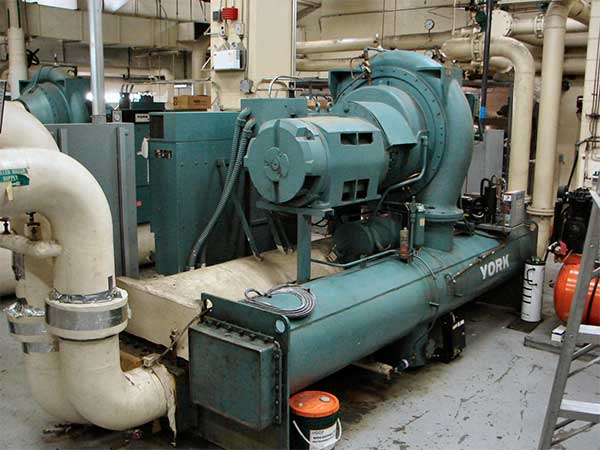

Water Chiller

When choosing a water chiller, it should be taken into consideration that it gives better results than air chiller. Because it has less fluid volume, it can absorb more heat, provide more consistent temperature control, and do all this in a quieter way. Due to the low density of the chiller systems, it can carry less temperature per unit weight in terms of air and heat conduction.

For example: When air is used, you need to pass 0.5 m3 of air per minute through the chiller to increase 103 Watts of heat to a maximum of 10 ° C. When coolant is water, it is enough to pass 0.144 liters of water through the chiller per minute.

If you think which chiller model to buy, you should consider the altitude disadvantage of air cooling. You can choose water chiller systems because they perform the same as they rise above sea level.

If you say how to choose a chiller, you should also compare the sound they make while working. Water chiller systems are more comfortable working environments with less sound generating units. As the speed pump circulates a small amount of liquid, the sound is low. Remote positioning of the recirculation pump, radiator and fan also reduces the total volume. Therefore, it will be more advantageous to choose water chiller models.