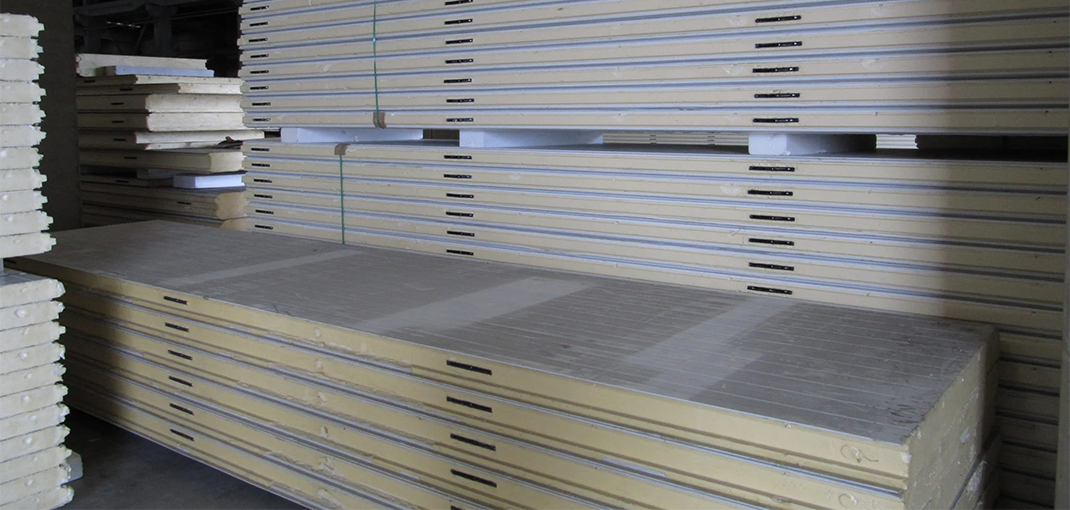

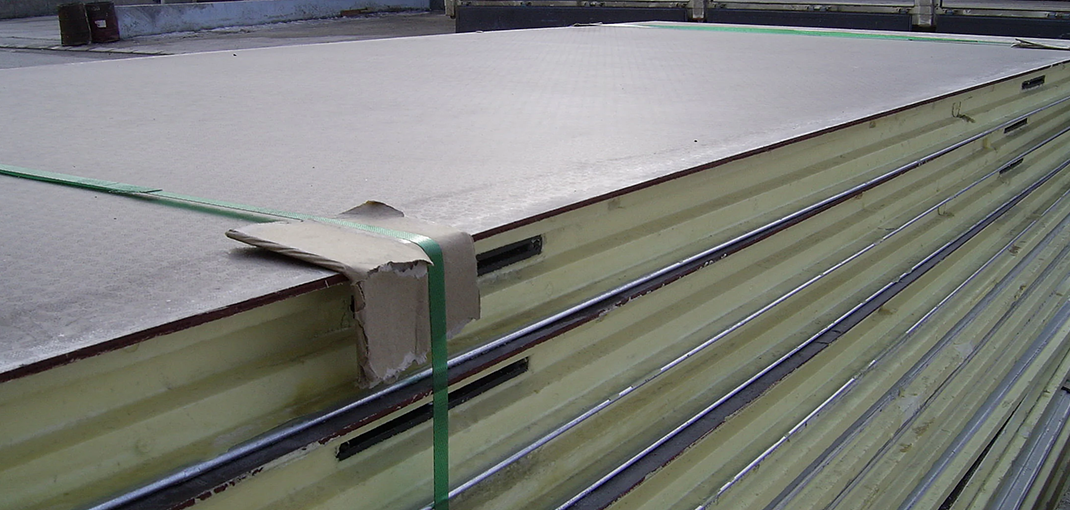

Cold storage floor and insulation panels can be easily mounted on the steel construction without the need for concrete on the floor slabs. A locked cold room panel can be locked to another panel with a specially designed eccentric system. The locking system ensures that the panel structures are mounted and disassembled without being damaged.

Cold store floor and insulation panels prices; It is affected by factors such as material quality, panel and tank size. Panels are an integral part of cold storage systems. One of the most essential components for floor insulation and thermal insulation is the cold storage floor panel. These panels are; It is economical, aesthetic and durable. It reliably protects the building from external atmospheric conditions.

Cold Storage Floor and Insulation Panels Technical Specifications

The expiration date is a very important factor for many products. Because when these products expire, high rates of financial loss are experienced. In order to extend the shelf life of the products, cold stores should be cooled exactly as desired. For example, insufficient or poor quality insulation materials can prevent efficient cooling.

Cold storage floor panel reduces your energy costs thanks to its CE certified polyurethane filling that provides high thermal insulation . It helps to maintain the quality of the products in the cold storage for long periods. The dimensions of the floor panels differ according to the usage area and type.

- It can be produced in 80mm – 100mm – 120mm – 150mm thicknesses.

- It can be produced up to 115 cm wide and 13.5 meters long as standard.

Cold Storage Floor Insulation

Floor panels consist of two parts, the lower and the upper surface. These panels are generally 10 mm thick and the upper surface is hexagonal textured. This part is designed using plywood material made of original birch wood .

The bottom surface is mostly 0.5 mm thick and is produced by filling polyurethane between polyester coated galvanized sheet metal. Polyurethane stands out among insulation materials with its high thermal insulation feature. Polyurethane filling; It is carried out in the dimensions of 40-42 kg/m³ and under high pressure.

So what is a cold room panel? Cold room panels produced for use in cold stores offer economical, hygienic and heat insulated solutions. Teknotek Cooling Systems; manufactures many cooling systems, including cold air panels . You can contact us to forward your order requests or to get information about cold room panel prices .