Cooling Panels ensure that the cold chain of foods, also known as the cooling chamber, is kept unbroken. They are insulation panels that can be adjusted to the desired degree regardless of the weather in the outdoor environment.

Cooling Panels are one of the biggest advantages of the panels that they save energy due to high insulation. Panel sizes can be designed according to all kinds of needs. It is produced from galvanized sheets that are hygienic in terms of use and that you can use for many years without any problems.

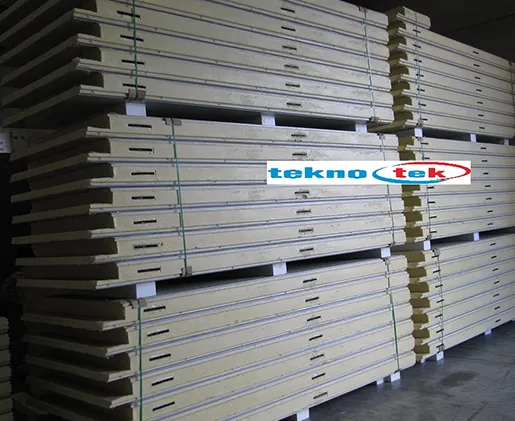

Cold Room Insulation Panels

In addition to foodstuffs, chemical and medical products also offer thermal insulation solutions in which contact with air is cut off and controlled. Cold insulation panels, which do not leak air and prevent heat loss, are produced in all lengths up to 1200 cm in width of 114 cm, and panel thicknesses are produced in ranges of 6 to 20 cm. One of the biggest advantages is that it maintains the desired temperature and controls heating and cooling. Thanks to easy assembly and fast installation, time and economy can be saved. The smooth and hygienic surface of the panels offers convenience during the cleaning phase. These panels, also known as sandwich panels, consist of strong insulation materials.

As a result of the features of the cold room panels and the production of them in the dimensions and thicknesses specified according to the project, the price varies. Cold insulation panels, which are one of the most important factors of the cold chain, are mounted with the ability to pass into each other in the form of male and female and offer convenience to the user such as growth, shrinkage and position change. Thanks to their isolation from outdoor weather conditions and the continuous controllability of the air temperature inside, they offer an environment where foods can be consumed fresh and safely for a long time.

Thanks to the insulated materials used in the installation of cold rooms, they are not affected by the climatic conditions outside, while they create areas where chemical and medical products can be stored and stored for a long time. These warehouses, whose walls and roof are generally made of polyurethane foam filled panels between sheet metal, offer a long service life. There are three types of cold storage panels:

- Industrial Panels: They are produced according to the desired size and specifications in cold storages.

- Ceiling Panel: They are produced in 60- 80- 100- 120- 150- 200 mm thickness.

- Floor Panel: They are produced with a width of 1110mm.

Refrigeration insulation panels are galvanized, formed with metallic zinc coating on steel. The aim here is to increase the resistance of the steel and help protect it from oxidation and chemical effects. Panels are often preferred because of their longevity and portability. It can be easily assembled and has advantages in terms of price due to its low cost.