If you are wondering what is industrial cooling, you can obtain the details in our article. Cooling device can be defined as a system that cools a commercial product or moistens the air in commercial facilities. These refrigerants use a vapor compression or absorption cycle to cool.

Types of Industrial Chillers

A chiller has an energy cooling from 1 to 1000 tons. There are three different types of chiller: Air, Water and Evaporative chiller. There are four subcategories in each three types of categories: Piston, Centrifuge, Screw and Absorption chiller. Whereas the first three types have electric motors, absorption chiller works by using steam or gas turbines. An absorption chiller is powered by a heat source such as steam and does not consist of electronic parts moving.

Industrial Chiller Components

Mechanical chillers have four basic components: Evaporator, Compressor, Condenser, Expansion valve. The evaporators in the chiller run at lower pressure. And they works in lower temperature than the condenser.

Compressor Types in Industrial Chillers

Reciprocating Compressor: A piston compressor is a compressor using pistons that is driven by a crankshaft. It is used to deliver a small amount of coolant at very high pressure. Piston compressors can run dual voltage and can have horsepower from 3 to 60. Piston compressors are generally semi-hermetic compressors.

Centrifugal Compressor: Centrifugal compressors are usually the first choice of firms. The biggest reason is that they have less moving parts. Besides, they have high energy savings and also higher cooling power than a piston compressor which is in similar dimensions. Centrifugal compressors are suitable for low-pressure places such like volume ventilation fans, cooling units and air circulation systems. The centrifugal compressor works using the centrifugal force applied to an air mass to provide compression. Standard capacities range from 60 to hundreds of tons. These are hermetic (sealed) and magnetic bed compressors. They run from 230 to 460 volts.

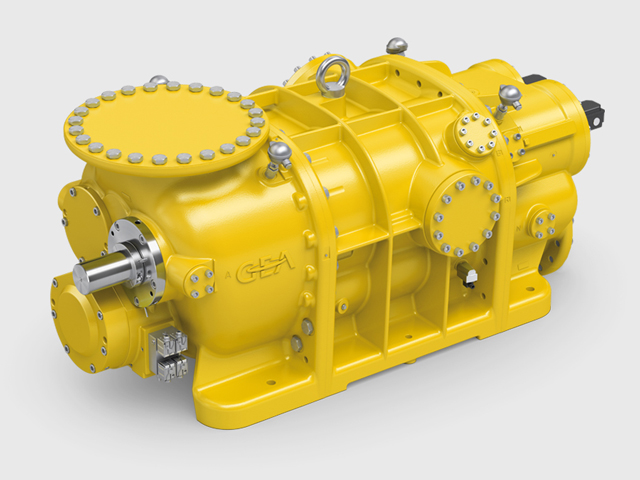

Screw Compressor: There are two screws (male / female) in the screw compressor which is assembled in the fixed body. When the rotors are rotating, the gas is compressed by direct volume reduction between the two rotors. These compressors are also semi-hermetically sealed compressors. They run on dual voltage and range from 40 to 1000 horsepower. There are also single screw compressors which use a single rotary screw passing through the two-star wheel in order to provide compression.

Maintenance of Industrial Chillers

Industrial chillers are designed to operate in the highest efficiency. Maintenance steps made regularly ensure that your chiller performs at an optimized efficiency level.

Industrial Chillers Location

The group of large industrial chillers should be located in mechanical equipment chambers within the building and close to the area of cooling. Depending on the size of the chiller and compressor, some industrial chillers can be found near the area. Sometimes it can also be completely placed outdoors. Our experienced team will help you to find the right solution for your business. Consult the Teknotek team for the best and most efficient cooling systems for your company.